Jiangsu Taihaokang New Material Co., Ltd.

Focusing on the research and production of plastic honeycomb panels, tailor-made

Tel:008618550057918

Email:chuying0378@163.com

Jiangsu Taihaokang New Material Co., Ltd.

Focusing on the research and production of plastic honeycomb panels, tailor-made

Tel:008618550057918

Email:chuying0378@163.com

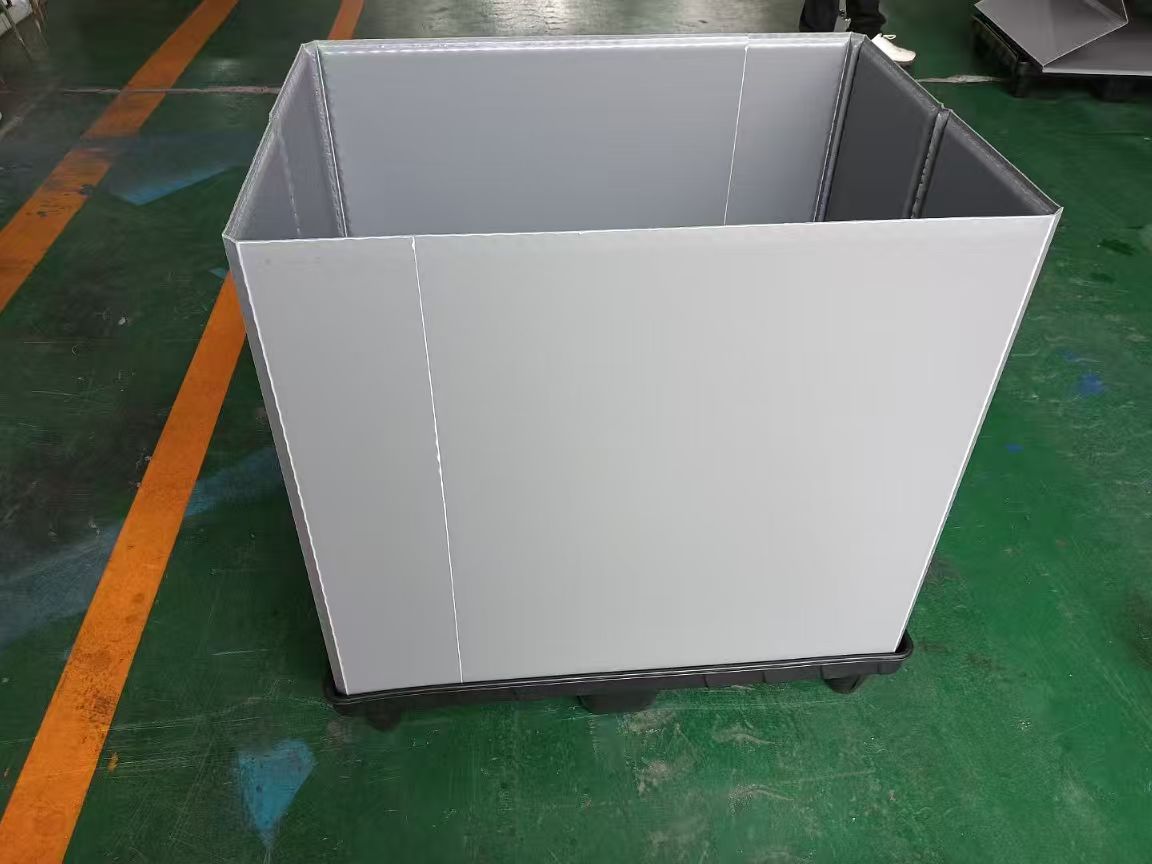

Packaging scheme for car headlight panel box

Time: 2024-04-15

Click: 281 times

How to use a bumper box to protect and transport the car's headlights before assembly, in order to reduce the damage rate of the headlights during assembly. With the increasing popularity of cars, the probability of rear end collisions during driving increases. More and more car owners are finding that the car lights are extremely vulnerable to damage. How should the car lights be protected before assembly.

The car lights are familiar to everyone and are fragile. Moreover, if the surface is scratched, it will also leave an impression on the car's lighting. The old car after leaving the factory will leave an impression on the consumer's trust in the brand. When choosing packaging for car lights, priority should be given. The production and logistics mode of the host factory, as well as the distance from itself to the host factory, often do not consider the issue of recycling and packaging shipping costs for manufacturers who are closer to the host factory. Suppliers who are far away should consider packaging and recycling costs. In general, for car lights supplied nearby, injection molded turnover boxes that can be used for packaging will be selected. The advantage of this is that there is no need for reverse packaging, and third-party logistics can directly deliver and put them online. Of course, the lining design of the turnover box also needs to consider the different requirements of different car lights.

And for suppliers who are farther away, they need to consider the cost of packaging and recycling when supplying car lights. In this case, manufacturers will prioritize packaging with plastic crates. In terms of internal protection, manufacturers generally have several different options. One way is to directly use paper knife cards to separate each product in the inner packaging, discard the inner lining after use, and recycle the outer box. Another method is to use a hollow board knife to cut and assemble the hollow board into grids of different sizes. To protect the car lights from transportation bumps inside the enclosure. At this time, considering the risk of scratches inside the enclosure, cars and others usually use bubble bags for packaging protection.

At the same time, it plays a buffering role for the car lights inside the fence box knife card. There are many other ways to package car lights in the surrounding box, such as using EVA material and silicone material. I will introduce them one by one next time.

<< Previous page

Next page >>